In the modern health industry, capsule supplements have become an important part of people’s daily lives. Whether it’s vitamins, minerals, or herbal extracts, capsules are favored for their convenience, accurate dosage, and ease of storage. So, How is capsule supplement manufacturing? This article will comprehensively analyze the production process of capsule supplements, from raw material selection and production technology to quality control and regulatory requirements.

Raw material selection and formulation design

Selection and Standards of Active Ingredients

Active ingredients include Vitamins, Minerals (e.g., Mg2+, Zn2+, and Estratti di erbe (e.g., Curcumin, Ginsenosides).

Selection Criteria:

- Alta purezza: The purity of the core active substance must be greater than 99% ($> 99\%$) to ensure accurate dosing and stable efficacy.

- Sourcing Certification: Preference must be given to traceable and certified raw materials, such as those with Organic Certification or Non-GMO Verification. These certifications ensure safety, sustainability, and environmental compliance.

- Standardized Extracts: For herbal raw materials, Standardized Extracts should be chosen to ensure a consistent content of the active marker compounds in every batch.

Selection of Excipients (Auxiliary Materials)

Excipients are used for shaping, ensuring smooth production, and enhancing bioavailability.

| Material Type | Esempi comuni | Funzione primaria | Confronto |

| Filler | Microcrystalline Cellulose (MCC), Lactose | Adds volume to tablets/capsules for accurate filling. | MCC is natural, inert, and offers excellent flowability. |

| Lubricant | Magnesium Stearate | Reduces friction between powder and machinery, improving production efficiency. | Widely used, but high doses can affect disintegration time. |

| Capsule Shell | Gelatina | Animal source, low cost, good stability. | Not suitable for vegetarians; ethical considerations. |

| HPMC Vegetarian Shell | Plant-based source, suitable for vegetarians and religious restrictions. | Slightly higher cost; more sensitive to moisture. |

Formulation Development and Testing

Dosage Calculation: Precisely determine the amount of active ingredients based on clinical studies and the Recommended Dietary Allowance (RDA) or Tolerable Upper Intake Level (UL).

Compatibility Assessment: Evaluate all raw materials (actives and excipients) in the formula for potential chemical reactions or physical interactions to prevent degradation of active components.

Test di stabilità:

- Accelerated Aging Test: The finished product is subjected to extreme conditions (e.g., high temperature 40℃ and high humidity 75% RH to predict shelf life in a short period. This ensures efficacy remains at least 90% of the label claim throughout the storage period.

Sustainability and Clean Label Trends

Modern formulation emphasizes sustainability and “clean labels”:

- Use of Plant-Based Ingredients: Maximize the use of botanical extracts and plant proteins, replacing animal-derived components.

- Reduced Reliance on Animal Collagen: Shift towards ingredients that promote endogenous collagen production (e.g., Vitamin C, Biotin) or vegan alternatives to meet vegetarian and ethical consumer demands.

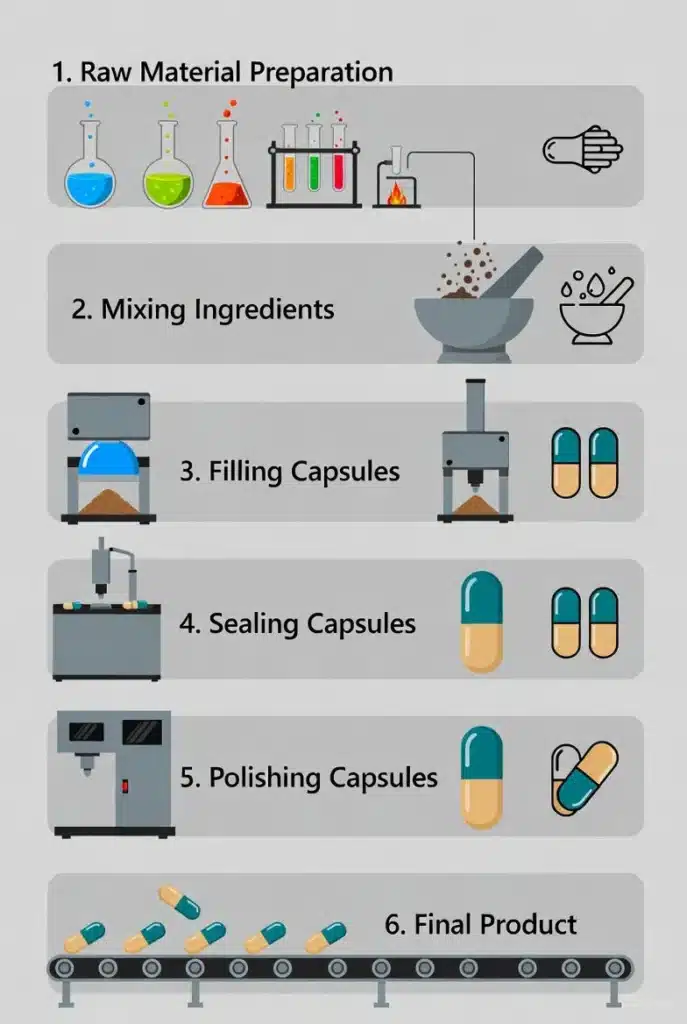

Capsule Supplement Manufacturing Process

The manufacturing process for capsules involves filling pre-formed shells with powder or granules, adhering to strict GMP (Good Manufacturing Practice) standards.

🏅 Raw Material Preparation and Pre-treatment

- Weighing: All active ingredients and excipients are precisely weighed according to the batch formula.

- Milling and Sieving: Materials are ground to the required fineness and passed through a sieve to remove lumps and impurities, thereby ensuring uniform particle size distribution.

🧪 Blending

- Dry Mixing: All weighed and processed powdered materials are mixed uniformly in specialized blenders (e.g., V-blenders, three-dimensional mixers). Achieving homogeneity is crucial for ensuring accurate and consistent dosing in every capsule.

- Lubricant Addition: Lubricants (such as Magnesium Stearate) are added in the final stage of blending to enhance the powder’s flowability, which is essential for efficient filling.

💊 Encapsulation

- Capsule Shell Separation: An automatic or semi-automatic capsule filling machine opens and separates the pre-formed capsule shells.

- Powder Filling: The uniformly blended powder is then filled into the lower body (or container) of the capsule shell.

- Closing and Locking: The upper part (cap) of the capsule is rejoined onto the lower body and tightly locked, ensuring the containment of the contents and preventing leakage.

✨ Polishing and Inspection

- Polishing: A capsule polishing machine is used to wipe away any residual powder from the capsule surface, resulting in a smooth and clean finish.

- Weight Check: Random samples are checked for capsule weight variation to verify the consistency and accuracy of the filling dosage.

- Metal Detection: The final product is screened for any potential metal contaminants to ensure consumer safety.

📦 Post-Processing

- Primary Packaging: The finished capsules are packaged into the containers that directly house the product (e.g., bottles, blister packs).

- Secondary Packaging: This involves placing the primary packages into cartons, applying final labeling, and boxing for shipment.

- Finished Product Testing and Release: Final quality control checks, including physicochemical and microbiological testing, are performed. The batch is released for distribution only after full compliance with all quality specifications is confirmed.

Equipment and Facility Requirements

High-quality supplement manufacturing relies on advanced equipment and facility layouts that comply with Good Manufacturing Practice (GMP) guidelines.

I. Core Production Equipment List

The following table outlines the essential equipment required for a capsule or tablet production line, focusing on function and cost range.

| Equipment Name | Core Function | Price Range (RMB) |

| Blender (e.g., V-type, 3D Mixer) | Ensures uniform mixing of raw material powders | ¥ 20k – 150k |

| Capsule Filler or High-Speed Tablet Press | Dosage form shaping (filling powder or pressing tablets) | ¥ 100k – 500k |

| Drying Equipment (e.g., Fluidized Bed Dryer) | Quick and even drying of wet granules (for wet granulation) | ¥ 80k – 300k |

| Automatic Packaging Machine (Bottling/Blister) | Final product packaging, ensuring sealing integrity | ¥ 100k – 400k |

| Quality Detection Instruments (e.g., X-ray Scanner) | Checks product weight, hardness, and detects metals or contaminants | ¥ 150k – 800k |

II. Facility Layout and Environmental Control

The facility must be scientifically partitioned according to the workflow and strictly control environmental parameters to prevent cross-contamination.

- Clean Room Zoning:

- Raw Material Area: Dedicated area for receiving, inspecting, and storing materials.

- Production Area (Clean Zone): The core manufacturing area that must maintain a high cleanliness level (e.g., Grade D or C).

- Packaging Area: Area designated for final sealing, boxing, and labeling of finished goods.

- Air Filtration System: An efficient HEPA Filter (High-Efficiency Particulate Air Filter) system must be implemented to ensure air cleanliness in the production area, controlling particulate and microbial contamination.

III. Scale Selection and Investment Estimation

- Scale Options:

- Laboratory Grade: Uses manual or semi-automatic equipment, suitable for small-batch formula testing and R&D.

- Industrial Grade: Utilizes fully automated production lines, with an investment typically exceeding RMB 500k to 2 million, targeting high capacity and low unit costs.

- Cost Estimate:

- The starting capital for a small production line (including basic equipment and simple cleanroom setup) is approximately RMB 100k to 500k.

- Under reasonable operation, the Return on Investment (ROI) period for a small line is generally 1 to 2 years.

Controllo qualità e conformità normativa

Strict Quality Control (QC) and comprehensive adherence to regulations are the foundation for the credibility and market viability of any health supplement brand.

I. End-to-End Quality Control (QC)

Quality control must be integrated into every stage of production to ensure product safety and efficacy.

- In-Process Monitoring (IPM):

- Weight and Dosage: Real-time monitoring of average weight and weight variation of capsules or tablets to guarantee dosing accuracy.

- Tempo di disintegrazione: Sample testing of the time required for tablets or capsules to disintegrate in a specified liquid. This is typically required to be less than 30 minutes to ensure active ingredient release.

- Batch Release Testing:

- Microbial Limits: Testing for $E. coli$, molds, and yeasts to ensure the product is free from microbial contamination.

- Heavy Metals: Testing for lead (Pb), arsenic (As), cadmium (Cd), and mercury (Hg). Levels must be well below national safety limits.

- Tasso di dissoluzione: Ensuring that the active ingredients dissolve at the expected speed and extent in the human digestive system for proper absorption.

- In-Process Monitoring (IPM):

- Weight and Dosage: Real-time monitoring of average weight and weight variation of capsules or tablets to guarantee dosing accuracy.

- Tempo di disintegrazione: Sample testing of the time required for tablets or capsules to disintegrate in a specified liquid. This is typically required to be less than 30 minutes to ensure active ingredient release.

- Batch Release Testing:

- Microbial Limits: Testing for $E. coli$, molds, and yeasts to ensure the product is free from microbial contamination.

- Heavy Metals: Testing for lead (Pb), arsenic (As), cadmium (Cd), and mercury (Hg). Levels must be well below national safety limits.

- Tasso di dissoluzione: Ensuring that the active ingredients dissolve at the expected speed and extent in the human digestive system for proper absorption.

II. Regulatory Framework and Labeling Requirements

Brands must operate within the regulatory frameworks of key global markets.

- Chinese Regulations: Strict adherence to the China’s Good Manufacturing Practice (GMP) for Health Food Production, which sets specific requirements for manufacturing, testing, and record-keeping.

- International Standards: Compliance with international market requirements, such as the US FDA’s (Food and Drug Administration) cGMP standards and the EU’s REACH regulation (Registration, Evaluation, Authorisation and Restriction of Chemicals).

- Requisiti di etichettatura: Label information must be truthful and accurate, including:

- Ingredient list and precise dosage.

- Allergen warnings (e.g., gluten, soy, nuts).

- Health claims and warnings for unsuitable populations.

III. Common Risks and Countermeasures

| Risk Issue | Root Cause | Solution/Countermeasure |

| Microbial Contamination | Raw material carryover, poor cleanroom air quality | Regular UV light sanitation of the production environment; strict employee hygiene protocols. |

| Stability Failure | Active ingredients degrade due to moisture, light, or heat | Use high-barrier packaging materials (e.g., aluminum blister packs), vacuum or nitrogen-flush packaging; controlled temperature/humidity storage. |

| Foreign Matter Contamination | Equipment wear, external pollutants | Use X-ray/Metal Detectors for in-line scanning; scheduled equipment maintenance and calibration. |

Case Study Lesson: The Kobayashi Pharmaceutical Red Yeast Rice Incident in Japan highlights that even natural ingredients, if improperly produced or stored, can generate harmful metabolites (such as inadvertently introduced citrinin) leading to widespread health issues and product recalls. Companies must strengthen toxicological monitoring of the raw material supply chain and intermediate products.

IV. Certification Pathways and Brand Trust

Certification is a highly effective way to gain market acceptance and consumer trust.

- Foundational Management Certification: Obtaining ISO 22000 (Food Safety Management System) certification establishes a systematic risk management framework.

- Premium Trust Certifications: Pursuing Organic Certification, Kosher, and Halal certifications to differentiate the product, significantly enhance brand trust, and improve international competitiveness.

Challenges, Innovation, and Future Outlook

I. Key Challenges

The industry faces several immediate hurdles:

- Raw Material Volatility: Supply chain disruptions and geopolitical instability often lead to unpredictable price and availability of core ingredients.

- Environmental Pressure: Increasing consumer demand and regulation for plastic alternatives mandate the shift toward sustainable packaging solutions.

- Personalized Production: The need to scale up capabilities for on-demand, customized supplements to serve individual genetic or dietary needs.

II. Innovation Drivers

Technology and science are driving key innovations:

- AI-Optimized Formulation: Utilizing Artificial Intelligence (AI) to rapidly analyze data and optimize ingredient ratios for enhanced efficacy and stability.

- Nanotechnology: Employing nano-encapsulation techniques to protect sensitive active compounds and significantly boost their absorption rate and bioavailability.

- Sustainable Materials: Developing advanced eco-friendly excipients and packaging, such as alginate-based capsule shells to replace traditional gelatin or HPMC.

III. Future Outlook

- Post-2025 Market Landscape: The market will increasingly be dominated by Smart Factories , characterized by full automation and real-time QC monitoring.

- E-commerce OEM Dominance: E-commerce Original Equipment Manufacturing (OEM) models will become the primary route for rapid product launches and scalable supply, catering to global direct-to-consumer needs.

Conclusione

This project outlines a robust foundation essential for success in the health supplement sector. We have defined the strict requirements for superior ingredient sourcing, GMP-compliant facility design, and comprehensive quality control. The production of compliant, high-quality capsules is not merely a manufacturing step, but the bedrock of the health industry’s trust and growth. We are now prepared to move from planning to execution.

Having grasped the details of the production process, the next step is to place it within a broader business and regulatory context. We recommend reading our for comprehensive guidance from concept to market.