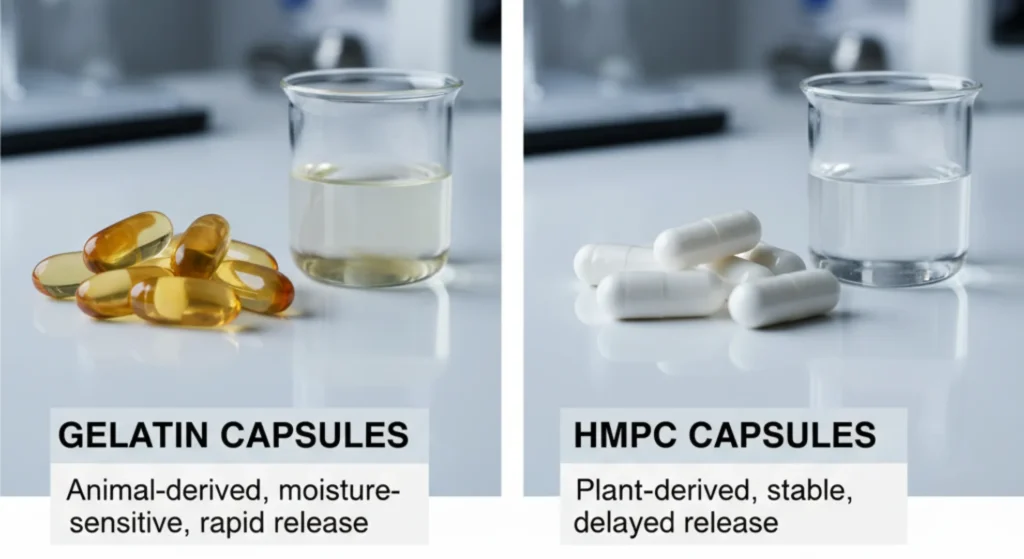

The fundamental difference between these two lies in their origin and stability profiles. Gelatin capsules are derived from animal collagen (bovine or porcine), offering a cost-effective solution with excellent oxygen barriers for standard formulations. However, their high moisture content can be risky for hygroscopic ingredients. In contrast, HPMC capsules are crafted from plant cellulose, catering to the global demand for clean-label and dietary-restricted products.

When evaluating Gelatin vs. Vegetarian (HPMC) Capsules, the latter stands out for its technical superiority in handling moisture-sensitive ingredients. With a significantly lower moisture content (3-8%), HPMC shells prevent brittleness and cross-linking, making them the preferred choice for herbal extracts and probiotics that require enhanced stability under varying storage conditions.

Gelatin vs. HPMC Capsules: The Ultimate Comparison

Choosing the right capsule shell isn’t just about “Animal vs. Plant.” It’s about matching the capsule’s chemical properties to your specific formula to ensure stability and shelf-life.

If you are in a rush, here is the technical breakdown of the three market leaders: Gelatin, HPMC (Vegetarian).

| Dimension | Gelatin Capsules | HPMC (Vegetarian) Capsules | Winner / Key Takeaway |

| 1. Raw Material Source | Animal Collagen (Bovine bone/hide, Porcine skin). | Plant Cellulose (Derived from Pine pulp or Cotton fiber). | HPMC (Aligns with the “Plant-Based” global trend). |

| 2. Target Audience | General mass market (Non-vegetarians). | Vegetarians, Vegans, Religious groups (Halal/Kosher). | HPMC (Universal acceptance; zero cultural barriers). |

| 3. Moisture Content | High (13% – 16%) Relies on water for flexibility. | Low (3% – 8%) Structurally stable; does not rely on water. | HPMC (Lower moisture = safer for sensitive ingredients). |

| 4. Hygroscopic Suitability | ❌ High Risk Hygroscopic powders pull water from the shell, causing the capsule to become brittle and shatter. | ✅ Excellent Low moisture content makes it ideal for moisture-loving powders and herbal extracts. | HPMC (Much higher formulation flexibility). |

| 5. Cross-linking Risk | ⚠️ Risk Exists Can cross-link with aldehydes or under high heat/humidity, leading to insolubility (hardening). | ✅ No Risk Chemically inert polymer; no cross-linking reaction ensures consistent dissolution. | HPMC (Superior physical stability). |

| 6. Oxygen Barrier | ✅ Excellent Naturally blocks oxygen effectively; great for Vitamin C or Fish Oils. | ⚠️ Average Permeability is higher than gelatin; sensitive ingredients may need secondary packaging. | Gelatin (Unless you use Pullulan or specialized HPMC). |

| 7. Heat & Storage | Sensitive Softens above 60°C; strict humidity controls needed (35-65% RH). | Robust Withstands higher temperatures and lower humidity without fracturing. | HPMC (Safer for shipping to hot/dry climates). |

| 8. Disintegration | Fast Dissolves rapidly in gastric acid (typically 5-10 mins). | Consistent Slightly slower start but predictable; less affected by pH variations. | Tie (Both meet global pharmacopoeia standards). |

| 9. Mechanical Strength | Strong, but becomes brittle if dehydrated. | Elastic and flexible; high breakage resistance during filling. | HPMC (Often lower defect rates on high-speed machines). |

| 10. Cost Profile | 💰 Low ($) Mature technology; commodity pricing. | 💰💰 Moderate ($$-$$$) Premium pricing, though the gap is narrowing as demand scales. | Gelatin (Still the king of cost-efficiency). |

💡 Decision Guide for Brand Owners

You can use this summary below the table to guide your readers to a conclusion:

- Choose Gelatin If:

- Your formula is a standard vitamin or mineral (non-hygroscopic).

- Budget is your primary constraint, and the target market is not strictly vegan.

- Your ingredient is highly sensitive to oxidation (liquid or oil-based formulas).

- Choose HPMC (Vegetarian) If:

- Your formula contains hygroscopic ingredients (e.g., Herbal extracts, Creatine, Amino Acids).

- You are selling Probiotics (low moisture content protects the bacteria).

- Your brand positioning is “Clean Label,” “Non-GMO,” or “Premium.”

- You export to regions with extreme climates (very hot or very dry).

Gelatin Capsules – The Traditional Standard

For over a century, gelatin capsules have been the backbone of the pharmaceutical and dietary supplement industries. Despite the rise of vegetarian alternatives, gelatin remains the most widely used capsule material globally, primarily due to its cost-efficiency and reliable mechanical performance.

What Are They Made Of?

Gelatin is a protein biopolymer derived from collagen. It is produced through the partial hydrolysis of collagen extracted from animal connective tissues.

- Bovine (Cow): The most common source, typically derived from bones or hides.

- Porcine (Pig): Derived from skin, often used for its clarity and lower cost, though it faces Halal/Kosher restrictions.

- Piscine (Fish): A premium marine alternative used for “Marine Collagen” marketing claims, though significantly more expensive.

The Technical Advantages (Why Manufacturers Love It)

1. Superior Oxygen Barrier (The “Freshness” Factor) One area where gelatin still outperforms standard HPMC is oxygen permeability. The tight molecular structure of gelatin creates an excellent barrier against oxygen transmission.

- Benefit: This makes gelatin the preferred choice for ingredients sensitive to oxidation, such as Vitamin A, certain enzymes, and fish oil powders. It acts as a natural shield, extending the shelf life of these volatile ingredients without the need for extra additives.

2. Cost-Efficiency Gelatin is a mature commodity. The supply chain is vast and established, making raw gelatin significantly cheaper than HPMC.

- Benefit: For brands producing high-volume, generic supplements (like standard Magnesium or Vitamin C) where margins are thin, gelatin provides the best ROI.

3. Machinability & Mechanical Strength Gelatin capsules are incredibly robust on high-speed filling machines (filling 100,000+ caps per hour). They have strong “locking” mechanisms and can withstand mechanical stress better than early-generation vegetable capsules.

The Limitations (The “Deal Breakers”)

While excellent mechanically, gelatin has chemical vulnerabilities that formulators must respect:

1. High Moisture Content (13% – 16%) Gelatin capsules need water to stay flexible. If the moisture drops below 13%, they become brittle and shatter like glass.

- The Risk: You cannot put hygroscopic (water-loving) ingredients inside them. Ingredients like Creatine, Glucosamine, or aggressive Herbal Extracts will suck the moisture out of the gelatin shell, causing the capsule to crack and leak.

2. Cross-Linking Risks This is the biggest chemical drawback. When gelatin is exposed to high heat, humidity, or aldehydes (found in some cinnamon flavors or aging herbal ingredients), the protein chains bind together tightly.

- The Result: The capsule creates a “pellicle” (a thin, insoluble skin) inside. It stops dissolving in the stomach, meaning the consumer passes the supplement without absorbing it.

3. Dietary & Cultural Restrictions In today’s global market, gelatin excludes a significant demographic:

- Vegetarians/Vegans (growing rapidly).

- Kosher/Halal consumers (unless specific Bovine-certified gelatin is used, Porcine is strictly forbidden).

Stick to Gelatin capsules if:

- Your market is price-sensitive.

- Your ingredients are not hygroscopic (moisture-absorbing).

- Your ingredients are highly sensitive to oxygen.

- Dietary restrictions (Vegan/Kosher) are not a priority for your target SKU.

HPMC Capsules – The Industry Favorite (Vegetarian)

While Gelatin is the traditional standard, HPMC (Hydroxypropyl Methylcellulose) has become the modern industry favorite. Originally developed as a niche product for strict vegetarians, it is now the go-to choice for premium supplement brands due to its superior chemical stability.

What is HPMC? (The Science)

HPMC, also known as Hypromellose, is a semi-synthetic polymer derived from plant cellulose.

- The Source: It typically starts with wood pulp (Pine) or cotton fibers.

- The Process: The cellulose is chemically modified to create a water-soluble polymer. While it is not “natural” in the same raw sense as simple starch, it is recognized globally as a safe, vegetarian, and non-animal material.

The Technical Advantages (The “Problem Solver”)

1. Ultra-Low Moisture Content (The “Dry” Advantage) This is HPMC’s “Killer App” for formulators. While gelatin holds 13-16% water, HPMC capsules contain only 3% to 8% moisture.

- Why this matters: It is the only safe choice for hygroscopic (water-loving) ingredients.

- The Scenario: If you put a highly hygroscopic herbal extract (like high-concentration Curcumin or Aloe) into a gelatin capsule, the powder will suck the water out of the shell, causing it to crack. HPMC prevents this, keeping the capsule intact and the powder dry.

2. Physical Stability (No Cross-Linking) Unlike gelatin, HPMC is a chemically inert polymer. It has no amino acid chains to react with aldehydes or reducing sugars (the Maillard reaction).

- Benefit: It will never cross-link. Even in high heat or humid storage conditions, HPMC capsules maintain their dissolution profile. A customer taking the vitamin on Day 1 will get the same absorption as a customer taking it on Day 365.

3. One SKU for All Markets Using HPMC simplifies inventory management. Because it is plant-based, it automatically qualifies for:

- Vegetarian & Vegan certifications.

- Kosher & Halal (without the complex supply chain tracing required for bovine/porcine gelatin).

- Non-GMO projects (usually). This allows brands to launch a single product that satisfies all dietary demographics simultaneously.

The Limitations (What to Watch Out For)

1. Oxygen Permeability HPMC is more “breathable” than gelatin. Its loose molecular structure allows more oxygen to pass through the shell.

- The Fix: If you are encapsulating ingredients that oxidize rapidly (like straight Vitamin C or certain enzymes), you may need to use colored/opaque capsules (to block light) and robust secondary packaging (like induction sealed bottles) to compensate for the airflow. Note: New generations of HPMC are improving this metric.

2. Cost Implications HPMC capsules are generally 20% to 40% more expensive than gelatin capsules. While this gap is narrowing as manufacturing scales up, it impacts the Cost of Goods Sold (COGS), particularly for low-margin, high-volume products.

📝 Summary: When to Use HPMC?

HPMC should be your default choice if:

- You are formulating with Probiotics (water kills bacteria; HPMC’s low water content keeps them alive).

- You are using Herbal Extracts or minerals that absorb moisture easily.

- Your brand targets the “Premium,” “Clean Label,” or “Plant-Based” market.

- You want to avoid any risk of the capsule hardening (cross-linking) over time.

The Decision Matrix – How to Choose the Right Capsule?

There is no such thing as a universally “perfect” capsule. The right choice depends on balancing three critical variables: Formulation Chemistry, Target Audience, and Cost of Goods Sold (COGS).

Use this decision matrix to navigate your specific project needs.

Scenario 1: The “Moisture Sensitivity” Test

Does your formula contain hygroscopic ingredients (ingredients that readily absorb moisture)?

- Examples: Herbal extracts (dry), Probiotics, Creatine, Amino Acids, SAMe.

- The Verdict: ✅ Choose HPMC (Vegetarian).

- Why: These ingredients are “thirsty.” If you put them in a Gelatin shell (which holds 13-16% water), the powder will suck the water out of the shell. The result? The capsule becomes brittle and shatters during shipping. HPMC’s low moisture content (3-8%) prevents this formulation disaster.

Scenario 2: The “Oxidation” Test

Is your primary ingredient highly sensitive to oxygen degradation?

- Examples: Fish Oils, Vitamin A, Vitamin C, certain Enzymes.

- The Verdict: ✅ Choose Gelatin or Pullulan.

- Why:

- Standard Choice: Gelatin. It has a naturally tight molecular structure that blocks oxygen better than standard HPMC.

- Premium Choice: Pullulan. If you need a plant-based option with oxygen protection, Pullulan is superior (300x better oxygen barrier than HPMC).

- Note: If you must use HPMC for an oxygen-sensitive ingredient, ensure you use a colored/opaque shell and high-barrier bottle packaging.

Scenario 3: The “Certified Organic” Test

Are you aiming for a USDA Organic or “100% Natural” claim on your label?

- The Verdict: ✅ Choose Pullulan.

- Why:

- Gelatin is animal-based (not organic unless specifically certified bovine from organic cows, which is rare/expensive).

- HPMC is semi-synthetic (chemically modified cellulose), so it cannot carry the USDA Organic seal in many jurisdictions.

- Pullulan is naturally fermented from tapioca starch without chemical modification, making it the gold standard for “Organic” lines.

Scenario 4: The “Budget” Test

Is your product a high-volume, low-margin commodity?

- Examples: Generic Multivitamins, Magnesium Glycinate, Zinc.

- The Verdict: ✅ Choose Gelatin.

- Why: Gelatin capsules are significantly cheaper than vegetarian options. For generic competitive markets where every cent of margin counts, Gelatin remains the economic winner.

Scenario 5: The “Liquid” Test

Are you filling the capsule with liquid or semi-solid oils?

- The Verdict: ✅ Choose Gelatin (or Specialized Banded HPMC).

- Why: Gelatin has a long history of success with liquid fills due to its robust oxygen barrier and sealing capabilities. While Liquid-HPMC technology exists, it often requires specific “banding” (sealing the joint) to prevent leakage, which adds manufacturing complexity.

🚀 Quick Decision Flowchart

- Is the ingredient Liquid/Oil?

- Yes -> Gelatin (Standard)

- No -> Go to Step 2.

- Is the ingredient Hygroscopic (Moisture sensitive) or Probiotic?

- Yes -> HPMC (Mandatory)

- No -> Go to Step 3.

- Is the target market strictly Vegetarian/Vegan?

- Yes -> HPMC (Standard) or Pullulan (Premium)

- No -> Go to Step 4.

- Is the ingredient extremely Oxygen Sensitive?

- Yes -> Pullulan (if Veggie) or Gelatin (if non-Veggie).

- No -> Gelatin (Best Value).

Conclusion

Choosing between Gelatin and Vegetarian (HPMC) capsules is not just a marketing decision—it is a chemical one.

- Gelatin remains the champion of cost-efficiency and oxygen protection for liquid/oil-based formulas.

- HPMC is the modern essential for stability, protecting probiotics and hygroscopic herbal extracts from moisture damage while satisfying the global demand for clean-label products.

Your capsule shell is the first thing your customer sees and swallows. It protects your expensive active ingredients. Making the wrong choice can lead to brittle capsules, oxidation, and customer complaints. Don’t let the shell compromise your formula.

Now that you understand the chemical differences between Gelatin and Vegetarian shells, you might have questions about sizes, printing, or coloring. Explore all these topics in our central guide: .”